The two halves are then shifted and welded to each other, as shown in Figure 1. Each cut consists of continuous modules made up of a semicircle followed by a small, straight section. Cellular beams are normally made from hot-rolled profiles with cuts that follow patterns (Sonck and Belis ). , when the openings are circular, these beams are called cellular beams.

The results from the numerical analyses were compared with the calculation procedures, which verified that the results were significant.Īccording to Abreu et al. The beams are submitted to uniform bending and concentrated load. In the boundary, conditions were restrained displacements in the axis X, Y, Z and rotation about X-axis, thus simulating the fork support. During the simulations, through non-linear geometric and physical analyses, geometric imperfections were varied, where lateral torsional buckling in cellular beams was considered as a function of the unrestrained length. In this study, numerical analyses are performed with cellular beams using Finite Element Method software. The condition that creates residual stresses in steel is the result of thermal and mechanical industrial processes. Additionally, the physical imperfections of rolled profiles result from the appearance of residual stresses. Geometric imperfections are represented numerically by an initial curvature. Geometrical imperfections result from a lack of straightness during fabrication of rolled profiles. Another important advantage of cellular beams is the possibility of passing utility ducts through the openings, which avoids cutting through the web of the beam or increasing the construction height, which occurs when the ducts pass under the beams. Obviously gross section might also be reduced by holes in the flanges, usually codes allow these to be ignored until they reach a certain percentage of holes which is the transition between gross (based on A_gross * Fy) and net section failure criteria (based on A_net x Fu).Cellular beams are appropriate for large spans with relatively small loads or for conditions in which strain dictates dimensioning.

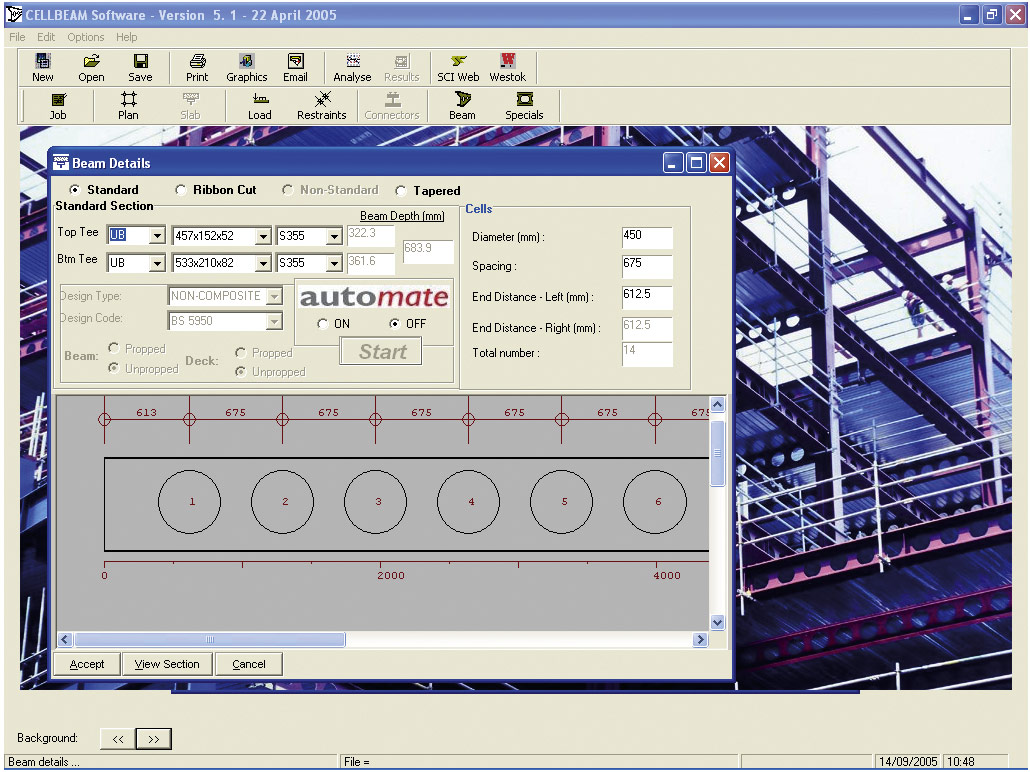

Castellated beam design software full#

Obviously the net section will govern at the web holes, and the gross section at the full section.

Just follow the same procedures you might follow to work out the effective section properties for any normal steel member (usually using b/t slenderness ratios).Ģ. usually you are calculating the section properties for the remaining top and bottom tee sections when they are under compression (either global axial load or axial compression induced by flexure). The AISC guide borrowed heavily from the established UK practices I believe.ġ.

I'd second a recommendation to read through the SCI P355 design guide robyengIT linked to as well, as its a great resource. If you read the rest of chapter 3 and the design examples as I'm sure it goes through and answers most of your questions, post back if there is anything thats not clear.

0 kommentar(er)

0 kommentar(er)